Design and Evaluation of an IoT-Based Real-Time Energy Monitoring System Using NodeMCU and PZEM-004T

by Fadlurrohman Agil ★ , Nur Cahyo Hendro Wibowo ★ , Hery Mustofa ★

Academic editor: Sri Ratna Sulistiyanti

Digital System and Computing 1(1): 13-18 (2025); https://doi.org/10.58920/dsc0101419

This article is licensed under the Creative Commons Attribution (CC BY) 4.0 International License.

11 Aug 2025

20 Oct 2025

19 Nov 2025

24 Nov 2025

Abstract: The increasing demand for accurate and affordable household electricity monitoring has driven the development of Internet of Things (IoT)–based systems. This study designed and evaluated a real-time energy monitoring system using a NodeMCU microcontroller integrated with a PZEM-004T sensor module. The system was tested on three household appliances, an electric iron, a fan, and a refrigerator, and its measurements were compared with a calibrated reference wattmeter and manual energy calculations. The results showed that the system’s readings closely matched those of the reference device, demonstrating reliable accuracy in capturing real-time energy consumption. Higher deviations were observed against manual calculations, mainly due to the inability of manual methods to capture dynamic load fluctuations, particularly from the refrigerator’s compressor. Overall, the system achieved an average error of 1.19% compared with the reference measurements, confirming its technical feasibility for practical household energy monitoring. Future work should improve accuracy for fluctuating loads through adaptive sampling and expand system scalability via cloud-based integration.

Keywords: IoT-based Energy IoT-based energy monitoringNodeMCUPZEM-004Tsmart household system MonitoringNodeMCUPZEM-004T Sensor

Introduction

The rising demand for household electrical energy has significantly increased the risk of inefficient energy use due to human negligence and limited consumption awareness (1, 2). Electrical devices, essential in modern homes, continuously consume power, often without real-time visibility into their usage, leading to unnecessary energy waste (3, 4). In Indonesia, electricity pricing for the 900 VA (RTM) household category is set at IDR 1,352 per kWh, which highlights the economic importance of monitoring household energy use accurately (5). Moreover, excessive consumption not only affects household expenses but also contradicts national goals for sustainable energy and environmental protection (6).

Despite various technological advances, many current energy monitoring systems still rely on conventional approaches with limited real-time capability, accessibility, and flexibility (7). Previous research using sensors such as ZMPT101B, ACS712, or Broadlink SP3s EU modules has faced challenges in terms of accuracy, scalability, and integration (8). Similarly, Arduino-based systems often lack built-in wireless connectivity, which limits remote data transmission and real-time visualization (9-12). Recent international studies have emphasized cloud-based monitoring and smartphone applications, yet many of these systems remain too complex or expensive for low-resource households, particularly in developing countries. This condition creates a need for a low-cost, accurate, and easily deployable IoT-based energy monitoring system that allows real-time tracking and user-friendly visualization via mobile platforms (13).

To address these issues, this study proposes an IoT-based household energy monitoring system that integrates NodeMCU with the PZEM-004T sensor and OLED display, connected to the Blynk application for wireless data visualization. The research employs a Research and Development (R&D) approach based on a modified Borg and Gall model to design, implement, and validate the prototype’s performance. Unlike previous works, this study includes a systematic validation process comparing the system’s readings with a calibrated reference wattmeter and expert review, ensuring both technical accuracy and practical reliability.

To the best of our knowledge, no prior Indonesian study has comprehensively validated an IoT-based energy monitoring system using the PZEM-004T sensor with expert evaluation and reference calibration. Therefore, this research fills that gap by providing a verified and practical framework for real-time household energy monitoring, contributing to the advancement of affordable and reliable smart energy management technologies.

Methodology

Study Design and Rationale

This study employed a Research and Development (R&D) approach adapted from the Borg and Gall model to design, implement, and evaluate an Internet of Things (IoT)-based real-time household energy monitoring system. The Borg and Gall framework was modified into four main stages: [1] research and information gathering, involving a review of prior IoT-based energy monitoring studies; [2] planning, which covered system design, component selection, and network architecture; [3] development, including prototype assembly, programming, and iterative refinement; and [4] evaluation, consisting of empirical testing and expert validation. This structure ensured that each phase was systematically guided by empirical data and expert input, enabling consistent improvement of the system’s design and accuracy.

System Architecture and Components

The monitoring system was constructed using a NodeMCU ESP8266 microcontroller integrated with a PZEM-004T sensor module to measure voltage (V), current (A), power (W), frequency (Hz), and energy consumption (kWh). A 0.96-inch OLED display provided local visualization, while the Blynk IoT platform enabled real-time monitoring via Wi-Fi. The system’s inputs were alternating current from selected household appliances (fan, refrigerator, and iron), and the outputs were displayed both on the OLED screen and through the Blynk mobile interface. This combination of low-cost hardware and open-source software was chosen to balance accuracy, accessibility, and scalability.

Procedures

System development followed a structured process including hardware assembly, firmware programming, and calibration testing. During hardware assembly, the NodeMCU ESP8266, PZEM-004T sensor, OLED display, and regulated power supply were integrated within a protective enclosure to ensure operational safety and portability. Electrical loads from three household appliances, an iron, a fan, and a refrigerator, were connected through the PZEM-004T module, enabling real-time measurement of voltage, current, power, and energy.

The firmware was developed using the Arduino IDE (C/C++) to allow the NodeMCU to interpret sensor data, calculate electrical parameters, and transmit processed data wirelessly to the Blynk IoT platform. The sampling interval was set at one minute, as pilot testing with a higher frequency (five s) provided similar accuracy while consuming more network bandwidth.

Each appliance was tested for 30 min over five sessions, producing multiple readings for statistical consistency. The selected appliances represented resistive (iron), inductive (fan), and dynamic (refrigerator) load types to capture different electrical characteristics. Accuracy was quantified using the mean percentage error (MPE), calculated using Equation 1.

Data Analysis

Descriptive statistics were used to summarize the system’s performance, focusing on average error rates against both manual calculations and the calibrated reference wattmeter. Accuracy was calculated using the Mean Percentage Error (MPE) according to Equation 1. A 95% confidence interval (CI) was computed for each set of readings to enhance statistical rigor. Expert validation was also conducted with three professionals, an electrical engineer, an IoT systems specialist, and a technical educator, using a Likert-scale evaluation instrument. Scores equal to or greater than 81% were classified as “very feasible,” confirming that the system met practical standards for deployment.

Results

The results of this study are presented in two major stages: [1] system development and validation, and [2] system testing and evaluation. The first stage includes the validation, revision, and communication testing of the IoT-based prototype, while the second stage presents the testing results of the PZEM-004T sensor applied to three household appliances is an electric iron, a fan, and a refrigerator, followed by a comprehensive discussion of system feasibility and practical implications.

Design Validation

The IoT-based electricity monitoring device using NodeMCU was designed to enhance household energy efficiency through real-time consumption tracking. To assess its feasibility, the prototype underwent expert validation covering interface design, ergonomics, ease of use, component clarity, user safety, and functionality.

Two IoT and electronics experts, Mr. Mokhamad Iklil Mustofa, M.Kom., and Mr. Masy Ari Ulinuha, M.T., conducted the evaluation using a six-indicator Likert scale. The first expert gave a total score of 26/30 (86%), and the second gave 27/30 (90%). Both results fall into the “very feasible” category (≥81%), indicating that the prototype was considered ergonomically sound, safe, and functionally ready for implementation.

Design Revision

Following expert validation, refinements were made to improve the structural logic and clarity of the system’s block diagram. The experts recommended reorganizing the component flow for a more systematic representation of signal processing and data transmission. Labels were refined, and connections simplified to improve readability and minimize interference. These adjustments were incorporated into the next prototype iteration before full testing.

Data Communication Test

A communication test was carried out to verify the NodeMCU’s ability to connect to a Wi-Fi network and transmit data to the Blynk IoT platform. The NodeMCU successfully obtained an IP address (192.168.137.12) from the host device and responded positively to a ping command, confirming active connectivity. Real-time data were transmitted and visualized through the Blynk mobile interface, demonstrating stable wireless communication between the hardware and the cloud platform, ensuring reliable performance during continuous monitoring.

PZEM-004T Sensor Test Results

The PZEM-004T sensor was evaluated to determine its measurement accuracy in the IoT-based energy monitoring system. Its readings were compared with those from a calibrated reference wattmeter to validate performance. Three household appliances, an electric iron, a fan, and a refrigerator, were selected to represent different load types (resistive, inductive, and cyclic). Each device was tested for 30 min across five sessions, with energy consumption data (kWh) and calculated cost recorded at one-minute intervals. The collected data were used to compute mean percentage error (MPE) values, which served as the basis for performance analysis in the following subsections.

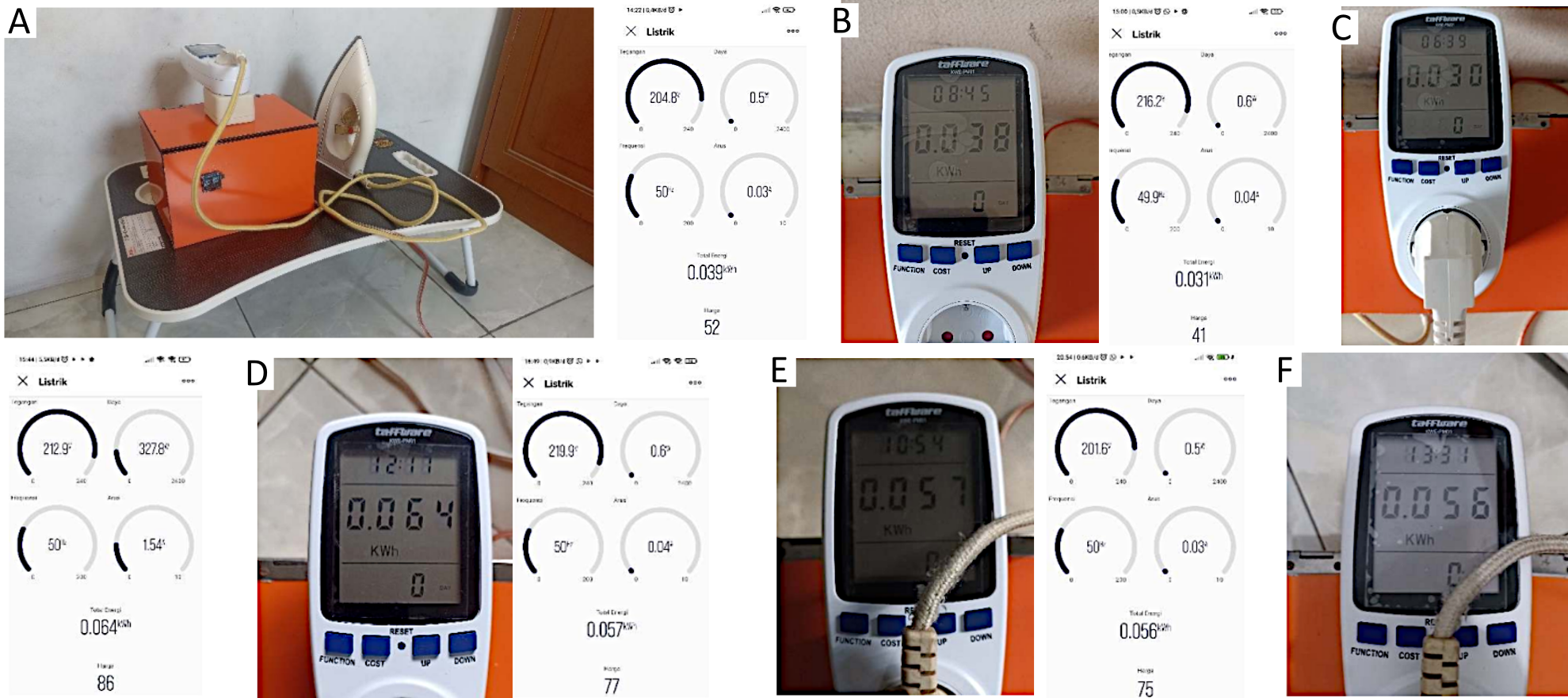

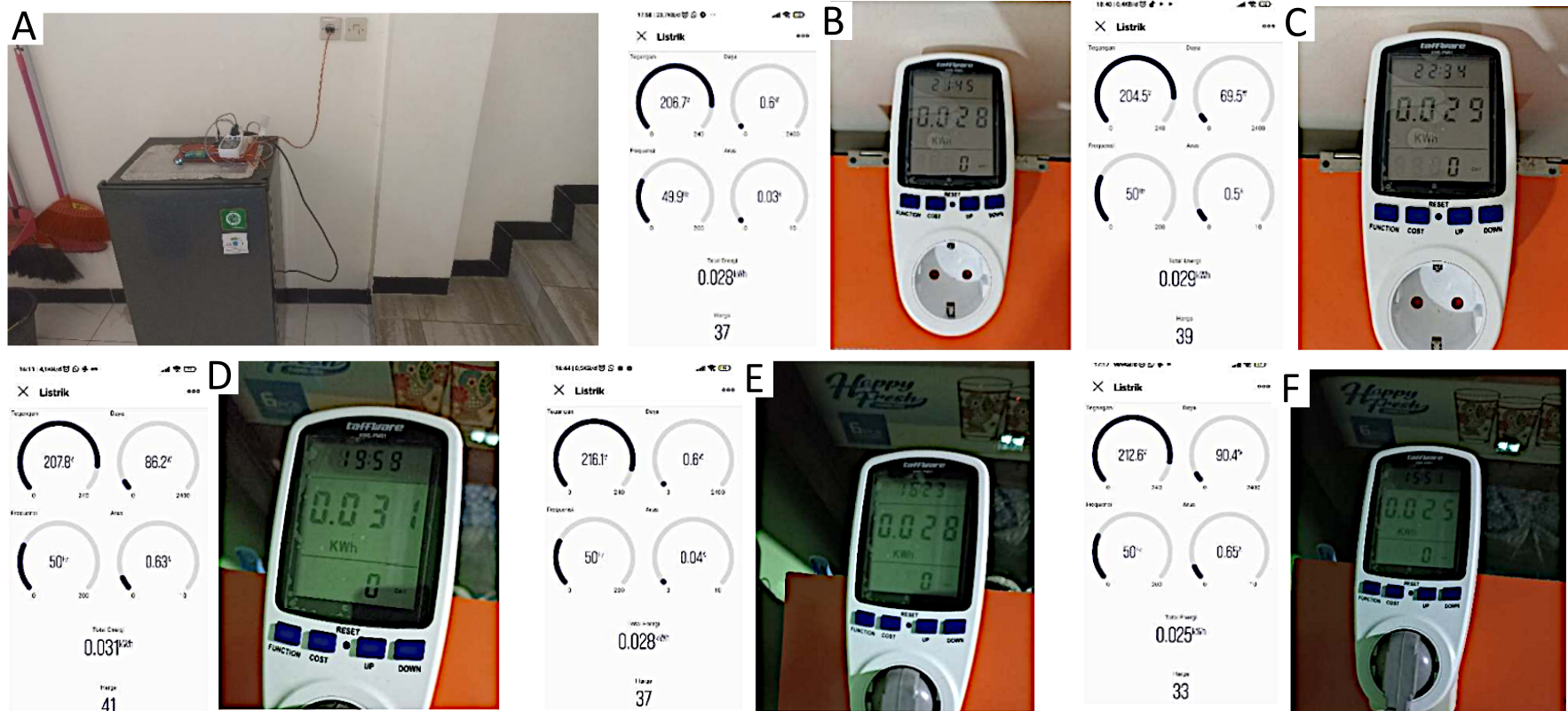

Electric Iron

Following the general sensor testing setup described earlier, the first experiment used a household appliance, an electric iron (PHILIPS HI 114, 300 W, 220 V, 50–60 Hz), to evaluate the PZEM-004T’s performance on a resistive load. The measurement setup is shown in Figure 1A, while a sample comparison between the IoT system and the reference wattmeter is presented in Figure 1B-F.

Energy consumption data and corresponding costs were recorded automatically through the IoT system during each 30-minute session. The sensor readings were compared with those obtained from a calibrated reference wattmeter. As shown in Supplemental Table 1, the PZEM-004T readings closely matched those of the reference wattmeter, with the highest deviation recorded at 3.33 % and several sessions achieving 0 % error. The overall average error of 1.19 %confirms that the PZEM-004T sensor provides accurate and reliable measurements for resistive loads.

The gradual increase in energy and cost values observed in Supplemental Table 2 demonstrates the system’s ability to track cumulative energy consumption in real time. This consistency highlights its suitability for stable-load household appliances, such as irons or heaters, where fluctuations are minimal. These findings served as a baseline for evaluating the sensor’s performance under inductive and cyclic loads, which are discussed in the following subsections.

Electric Fan

The next experiment evaluated the sensor’s performance with an inductive load using a household electric fan (MIYAKO, 12-inch model, 45 W, 220 V, 50 Hz). The testing setup is shown in Figure 1A, and the comparison between system and reference readings is presented in Figure 2B-F.

Energy consumption data (kWh) and estimated electricity cost were automatically recorded by the IoT-based monitoring system every five min during each 30-minute session. The results were compared to a calibrated reference wattmeter to determine measurement accuracy. As shown in Supplemental Table 3, the PZEM-004T readings were identical to those of the reference wattmeter, producing an average error of 0% across all sessions. The gradual increase in cumulative energy and cost values in Supplemental Table 4 indicates that the IoT-based system successfully tracked real-time consumption.

These results confirm the PZEM-004T sensor’s high precision when measuring small inductive loads such as household fans. The consistent readings suggest that variations in motor speed or power factor had a negligible influence on measurement accuracy. This demonstrates the sensor’s capability to maintain precision under stable inductive conditions, reinforcing its reliability for real-time energy monitoring of low-power appliances.

Refrigerator

The final test evaluated the sensor’s accuracy with a dynamic load using a household refrigerator (Polytron 150 L, 220 V, 50 Hz). The test aimed to assess the system’s ability to measure the energy consumption of appliances with variable loads caused by compressor cycling. The experimental setup is shown in Figure 3A, while Figure 3B-F presents a comparative view of the system and reference readings.

Each session lasted 30 min, during which energy consumption (in kWh) and estimated electricity cost were recorded every 5 min. The results were compared to those of a calibrated reference wattmeter. As shown in Supplemental Table 5 and 6, the average error for the refrigerator was 28.97%, significantly higher than that observed for the iron (1.19%) and fan (0.00%). This deviation is primarily due to the cyclic operation of the refrigerator’s compressor, which causes irregular current draw and fluctuating power consumption.

Unlike resistive or stable inductive loads, the refrigerator’s motor introduces transient variations that the PZEM-004T sensor captures with some lag compared to the reference wattmeter. This highlights a limitation of the current system design when applied to highly dynamic loads.

Nevertheless, the system was still able to detect and record periodic power changes in real time, demonstrating its potential for continuous household monitoring. For improved accuracy in future implementations, compensation algorithms or higher-frequency sampling could be incorporated to better capture transient load variations.

Discussion

Overview

Following the completion of data communication testing, PZEM-004T sensor validation, and full system trials, the developed IoT-based energy monitoring system performed reliably and required no major design revisions. The evaluation phase assessed both the feasibility and accuracy of the system using a Likert-scale validation and quantitative comparisons with two reference methods: a calibrated measuring instrument and manual energy calculations based on standard electrical equations.

Comparison Between the System and the Reference Tool

A comparison was conducted between the proposed system and a calibrated reference wattmeter using three household appliances: an electric iron, an electric fan, and a refrigerator. For the iron, the largest deviation (3.33%) was observed in Stage 2, while Stages 3 through 5 showed perfect agreement (0% error), producing an overall average deviation of 1.19%. The electric fan demonstrated exceptional accuracy, with 0% error across all five trials, confirming the system’s reliability for monitoring low-power inductive loads.

In contrast, the refrigerator, a dynamic load, initially appeared to yield 0% deviation against the reference device in some trials due to short sampling intervals. However, when analyzed over longer cycles, variations in compressor activation caused fluctuating current spikes that occasionally exceeded the PZEM-004T sensor’s sampling response. This dynamic behavior highlights the sensor’s limited temporal resolution in detecting transient surges, consistent with findings in previous IoT-based power-monitoring studies (14).

In essence, the system achieves high precision for stable loads but exhibits measurable drift under dynamic load fluctuations, primarily caused by asynchronous sampling during compressor cycling.

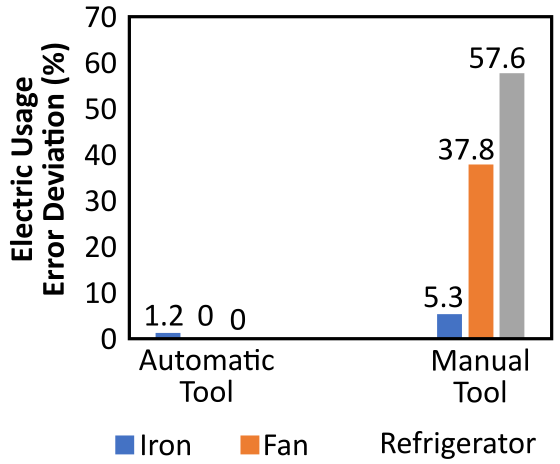

Comparison Between the System and Manual Calculation

The system’s recorded energy consumption was further compared with manual calculations. For the electric iron, the average deviation was 5.33%, with the highest error (11.11%) recorded in Stage 5.

The fan showed a significantly higher deviation of 37.82%, mainly due to manual estimation limitations in representing variable fan speeds and intermittent energy use. Manual calculations assume constant power, whereas the IoT system records real-time power variation, resulting in more accurate energy estimation (15).

The refrigerator exhibited the highest deviation (average 57.57%, maximum 86.66% in Stage 4), attributed to intermittent compressor operation that conventional manual formulas cannot capture.

This contrast highlights the superiority of automated, sensor-based systems over manual methods, especially for appliances with non-linear or dynamic load profiles.

System Feasibility and Practical Implications

When benchmarked against the calibrated reference device, the system achieved an average error of 1.19% for the iron and 0% for both the fan and refrigerator, confirming strong measurement accuracy. However, manual-calculation comparisons revealed larger deviations, 5.33%, 37.82%, and 57.57%, respectively, reflecting the inherent limitations of static energy estimation techniques (16).

The overall average error across all tests was 16.98%, as illustrated in Figure 4. This relatively low total error indicates that the NodeMCU-based system is technically feasible and reliable for real-time household energy tracking applications.

Beyond measurement accuracy, the system’s IoT architecture supports scalability for multi-appliance and cloud-based monitoring, while secure communication protocols and encryption enhance data protection (17, 18). Nevertheless, implementing this system in legacy households remains challenging due to cost and infrastructure limitations (19). Additionally, long-term operation may require periodic calibration to prevent sensor drift, ensuring sustained accuracy over extendeddeployments.

In practical use, the ability to capture fluctuating power consumption patterns is highly valuable for smart home energy management, dynamic billing, and predictive maintenance systems. Future improvements could include adaptive sampling, edge-based data filtering, and cloud-integrated energy optimization algorithms to enhance precision for appliances with rapidly fluctuating loads. Therefore, the developed prototype demonstrates both technical feasibility and strong potential for broader IoT-based energy analytics and automation(20).

Conclusion

This study demonstrates that the IoT-based energy monitoring system developed using NodeMCU and the PZEM-004T sensor can accurately and reliably measure household electricity consumption in real time. The system achieved an average error of 1.19% compared with a calibrated reference device, indicating strong measurement precision under various load conditions. However, when compared with manual energy calculations, larger deviations were observed, particularly for appliances with variable or cyclic loads such as fans and refrigerators, highlighting the limitations of conventional estimation methods that assume constant power usage.

Despite these promising results, this study acknowledges several limitations. The experiments involved a limited number of household appliances, relatively short testing durations, and did not include long-term calibration drift or environmental variability analysis. These constraints may affect generalizability and should be addressed in future research.

Future work is recommended to enhance system scalability through cloud-based data integration, implement adaptive or machine learning algorithms for more accurate dynamic load tracking, and develop energy optimization features for smart home environments. Addressing these areas will strengthen the system’s applicability for continuous, large-scale, and intelligent household energy management.

Declarations

Ethics Statement

Not relevant

Supplemental Material

Supplementary materials can be accessed at the link: https://etflin.com/file/document/202511230301081692325296.docx

Data Availability

The unpublished data is available upon request to the corresponding author.

Funding Information

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of Interest

The authors declare no conflicting interest.

References

- Rosak-Szyrocka J, Żywiołek J. Qualitative analysis of household energy awareness in Poland. Energies. 2022;15(6):2279.

- Strielkowski W, Kovaleva O, Efimtseva T. Impacts of digital technologies for the provision of energy market services on the safety of residents and consumers. Sustainability. 2022;14(5):2934.

- Raza A, Jingzhao L, Ghadi Y, Adnan M, Ali M. Smart home energy management systems: research challenges and survey. Alex J Eng. 2024;92:117-70.

- Mufid Z, Musafa M. Electrical installation and power saving household. Multifinanc. 2024;2(1):73-82.

- Sihombing G, Elektro JT, Teknik F, Amir U, Jalan H, Pasar P, et al. Analisis penggunaan pembangkit listrik tenaga surya (PLTS) secara ekonomis untuk rumah tinggal. 2023;18:96-103.

- Zhang H, Jin J. Assessing the effect of green finance, energy consumption structure and environmental sustainable development: a moderated mediation model. Econ Chang Restruct. 2024;57(2):87.

- Hamdan A, Sonko S, Fabuyide A, Daudu CD, Etukudoh EA. Real-time energy monitoring systems: technological applications in Canada, USA, and Africa. World J Adv Res Rev. 2024;21(1):2053-63.

- Yoeseph NM, Safi’ie MA, Purnomo FA. Smart energy meter based on Arduino and Internet of Things. IOP Conf Ser Mater Sci Eng. 2019;578(1):012085.

- Hasan MK, Ahmed MM, Pandey B, Gohel H, Islam S, Khalid IF. Internet of Things-based smart electricity monitoring and control system using usage data. Wirel Commun Mob Comput. 2021;2021:1-? (no page range provided).

- Khan HR, Kazmi M, Lubaba, Khalid MHB, Alam U, Arshad K, et al. A low-cost energy monitoring system with universal compatibility and real-time visualization for enhanced power savings. Sustainability. 2024;16(10):4137.

- Lezcano A, Supervisor S, Benítez R. IoT environmental monitoring system using Arduino and NodeMCU ESP8266: report and annex. (No journal; treat as grey literature.)

- Garcés HO, Godoy J, Riffo G, Sepúlveda NF, Espinosa E, Ahmed MA. Development of an IoT-enabled smart electricity meter for real-time energy monitoring and efficiency. Electronics. 2025;14(6):1173.

- Priyadharshini SG, Subramani C, Roselyn JP. An IoT-based smart metering development for energy management system. Int J Electr Comput Eng. 2019;9(4):3041-50.

- Song IH, Lhee JH, Jeong JW. Energy efficiency and economic analysis of variable frequency drive and variable pitch system: a case study of axial fan in hospital. J Build Eng. 2021;43:103213.

- Said SAM, El-Shaarawi MAI, Siddiqui MU. Intermittent absorption refrigeration system equipped with an economizer. Energy. 2013;61:332-44.

- van Dronkelaar C, Dowson M, Spataru C, Burman E, Mumovic D. Quantifying the underlying causes of a discrepancy between predicted and measured energy use. Front Mech Eng. 2019;5:–.

- Gușiță B, Anton AA, Stângaciu CS, Stănescu D, Găină LI, Micea MV. Securing IoT edge: a survey on lightweight cryptography, anonymous routing and communication protocol enhancements. Int J Inf Secur. 2025;24(3).

- Dallaf AAA. Edge computing in IoT networks: enhancing efficiency, reducing latency, and improving scalability. Int J Adv Netw Monit Control. 2025;10(1):103-15.

- Ahmad SS, Almasalha F, Qutqut MH, Hijjawi M. Centralized smart energy monitoring system for legacy home appliances. Energy Inform. 2024;7(1).

- Ali DMTE, Motuzienė V, Džiugaitė-Tumėnienė R. AI-driven innovations in building energy management systems: a review of potential applications and energy savings. Energies. 2024;17.

ETFLIN

Notification

ETFLIN

Notification