Characterizations of Swelling Granule of Clove Leaf (Syzygium aromaticum L.) Ethanol Extract

by Ayu Wulandari ★ , Gita Chintya, Muthmainah Tuldjanah, Rezky Yanuarty

Academic editor: Farid Menaa

Sciences of Pharmacy 3(1): 35-39 (2024); https://doi.org/10.58920/sciphar0301182

This article is licensed under the Creative Commons Attribution (CC BY) 4.0 International License.

15 Nov 2023

24 Jan 2024

27 Jan 2024

27 Jan 2024

Abstract: Cloves, scientifically known as Syzygium aromaticum L., hold promise as a potential antiulcer remedy due to their rich composition of compounds, including high levels of phenolic compounds such as eugenol, eugenol acetate, and gallic acid. To improve bioavailability in the gastric environment, this study focuses on optimizing and evaluating a swelling granule system derived from clove leaf extract. The granules were produced using wet granulation with Carbopol, HPMC, and their combination as polymer matrices. Results indicated favorable properties in the swelling granules, with the optimal composition of 210 mg Carbopol, 36 mg PVP, and 404 mg Avicel pH 101. These granules exhibited a uniform particle size distribution, with 90.1% below 149 µm and 9.9% distributed across mesh numbers 100, 80, and 40. The formula with Carbopol polymer showed superior flow rate, compressibility, and swelling capacity compared to other formulations. The interaction between Carbopol's C=O groups and HPMC's hydroxyl groups significantly influenced parameters, especially swelling capacity. Thus, when combining polymers, potential chemical or physical reactions should be considered. The wet granulation process effectively preserved secondary metabolite levels from clove leaf. Further tests are recommended to evaluate the granulation's effectiveness as a delivery system for clove leaf extract.

Keywords: Clove leavesMucoadhesive granulesGastroretentive

Introduction

Clove leaves are a plant with potential antiulcer properties due to their rich content of phenolic compounds such as eugenol, eugenol acetate, and gallic acid. They show significant potential in treating gastric ulcers and contain therapeutic flavonoids ideal for gastrointestinal disease treatment associated with Helicobacter pylori infection (1). It is reported that that secondary metabolites in clove leaves can increase gastric blood flow and mucosal synthesis (2). Other studies suggested that clove buds can inhibit significant anti-ulcerogenic activity in gastric ulcers and reduce lipid peroxidation levels in the stomach (3). Research by Zheng et al. (2020) stated that clove leaf flavonoids can have an anti-gastric ulcer effect by inhibiting gastric acid secretion, similar to how histamine (H2) receptor antagonists and PPIs work (4). However, the oral consumption of natural materials can expedite the absorption of their active components into the body or be excreted alongside feces. Therefore, a delivery system is required that can maintain their concentration in the gastric environment, allowing for optimized therapy.

The Gastroretentive Drug Delivery System (GRDDS) is a formulation or approach designed to prolong the residence time of drugs in the digestive tract (5). One of the functions of this system involves swelling, wherein the formulation can absorb surrounding fluids and remain buoyant, consequently leading to a prolonged gastric retention time (GRT) for the drug (6). Prolonged gastric retention enhances bioavailability, extends drug release duration, and reduces drug wastage (7). Polymers suitable for creating granules that readily absorb water and swell include Carbopol and HPMC. Carbopol, despite being insoluble in water, undergoes swelling and forms a gel-like system upon neutralization in water (8). This property is highly beneficial in maintaining clove leaf extract in the gastric environment and regulating its release (9). Similarly, HPMC swells in water and controls the release of substances (10).

Based on the above explanations, the researchers are interested in optimizing and evaluating the gastroretentive granules of clove leaf extract. This study aims to determine the optimal formula and evaluate the swelling ability of clove leaf extract granules using Carbopol and HPMC, expecting to optimize its therapeutic effects. The secondary metabolite levels of clove leaf were also assessed after granulation to evaluate the effectiveness of the wet granulation method employed in preserving these metabolite levels.

Experimental Section

Materials

The materials used were Clove (Syzygium aromaticum L.) leaf extract, distilled water (aquadest), 70% alcohol, aluminum foil, carbopol 974P, 96% ethanol, gloves, HPMC (hydroxypropyl methylcellulose) K15M, cotton, label paper, filtering paper, Avicel pH 101, and Polyvinyl pyrrolidone (PVP) (BASF).

Clove leaf powder extraction

A total of 800 grams of dried powdered plant material were subjected to maceration with 96% ethanol as the solvent for three rounds of 24-hour cycles in a container (jar). The resulting extract was then filtered using filter paper to obtain the filtrate. Subsequently, the filtrate was concentrated using a rotary vacuum evaporator at a temperature of 60°C, followed by further evaporation using a water bath until a concentrated extract was obtained.

Preparation of gastroretentive mucoadhesive granules

The granule was made by mixing the clove leaf extract, Avicel pH 101, carbopol, and HPMC, adhering precisely to predetermined formulas (F1 to F6). The mixing of these materials was done manually in a mortar, ensuring a thorough blend through manual grinding. Subsequently, a liquid binder solution of purified water and PVP was gradually introduced while the manual blending process continued. Once a consistent wet mass was achieved, the granulation process transitioned to a traditional method involving kneading and sieving. The damp mixture was kneaded for uniformity, and the resulting mass was sieved to obtain granules of the desired size. Following this step, the damp granules were carefully spread out and air-dried to remove excess moisture.

Dosage Characterization

Particle Size Distribution

The assessment of mucoadhesive granules' particle size distribution was conducted using a sieve shaker. This involved employing a set of sieves with standardized mesh sizes to separate and classify the granules based on their particle dimensions. The granules were carefully passed through the sieves, and the particles retained on each sieve were weighed. This process enabled the determination of the distribution of particle sizes within the granule sample, providing valuable information about the uniformity and range of particle dimensions.

Table 1. Mucoadhesive granule formula.

|

Material |

Rule |

Formula (mg) |

||||

|

F1 |

F2 |

F3 |

F4 |

F5 |

||

|

Clove (Syzygium aromaticum L.) leaf extract |

Active ingredient |

250 |

250 |

250 |

250 |

250 |

|

Carbopol |

Polymer |

- |

210 |

105 |

140 |

70 |

|

HPMC |

Polymer |

210 |

- |

105 |

70 |

140 |

|

PVP |

Binder |

36 |

36 |

36 |

36 |

36 |

|

Avicel pH 101 |

Filler |

404 |

404 |

404 |

404 |

404 |

Granules Compressibility

The evaluation of granule compressibility was carried out using a measuring glass and a jolting volumeter. Initially, 50 grams of granules were weighed, and these granules were then placed into the measuring glass, with the initial volume of the granules duly recorded. The jolting volumeter was then activated to deliver 100 taps, and once the apparatus came to a stop, the final volume of the granules was recorded. The percentage compressibility of the granules was computed using Equation 1.

Flow Rate

Initially, a predetermined quantity (X grams) of the mucoadhesive granules was carefully loaded into the hopper of the powder rheometer. The apparatus was equipped with a designated funnel through which the granules could freely flow. The mouth of the funnel was systematically opened, and the stopwatch was simultaneously activated to record the time it took for the entire granule mass to flow and drop into the collection vessel below. The experiment was conducted under controlled conditions, ensuring consistency in environmental factors such as temperature (25 oC) and humidity (45%).

Swelling Capacity

Granule swelling capacity was assessed by measuring weight changes after hydrating 200 mg of granules in 10 mL of 0.1 N HCL at pH 1.2, maintained at 37°C. Granules were extracted at 15, 30, 60, and 120-minute intervals, dried using filter paper, and reweighed to determine swelling capacity (Equation 2).

Equation 1

Equation 2

Metabolites Quantification in Granules

This quantitative analysis was carried out to determine the total content of secondary metabolites in the granules, comparing alkaloid levels with quinine as a reference, flavonoid levels with quercetin as a reference, saponin levels with sapogenin as a reference, and tannin levels with tannic acid as a reference. The test was done on only the best formula of granules having good characteristics.

Statistical Analysis

The physical quality evaluation data, which includes flow time test, particle size distribution test, compressibility test, floating ability test, and floating duration, were analyzed using the ANOVA method followed by Tukey post hoc analysis. Statistical analysis was performed using RStudio.

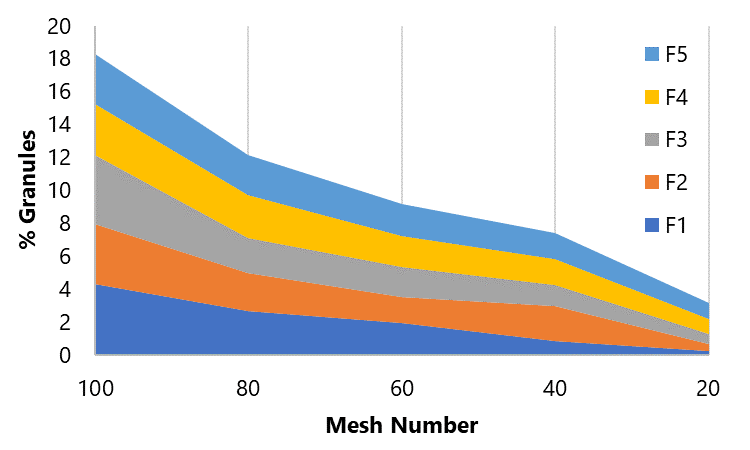

Figure 1. Particle size distribution of the granules.

Result

Characterization of gastroretentive mucoadhesive granules

Granules Size Distribution

The granules in each formula can penetrate mesh size 100 with a percentage ranging from approximately 89.95% to 90.1%. This indicates that the granules in each formula have an average size of around 149 µm, with formula 2 (F2) having the most granules of that size. About 10% of the granules in each formula exhibit a considerable size variation, as evidenced by granules left behind on each mesh number. In Figure 1, it can be observed that formulas 4 and 5 have a similar granule size distribution and tend to be distributed across various mesh numbers, although there were noticeable remnants on mesh number 100. A relatively good particle size distribution is evident in formula 1 (F1), where only a few granules are left on larger mesh sizes. This is followed by formula 2 (F2) and 3 (F3).

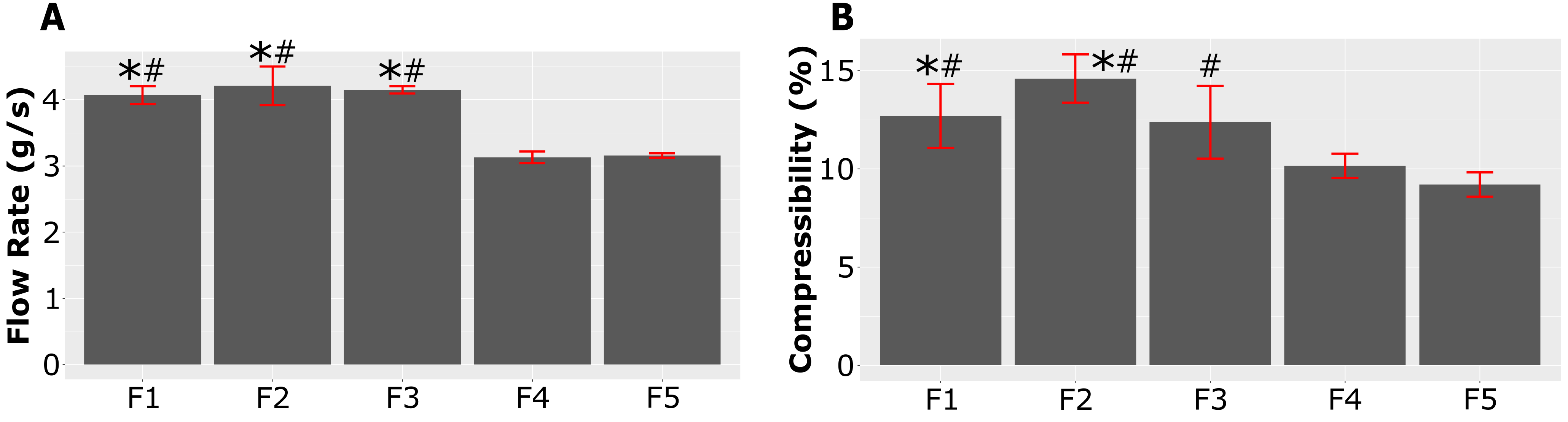

Granules Flow Rate

and Compressibility

Granule flow rate and compressibility are parameters used to assess the granules' ability to progress to the tablet production stage. The granules must be capable of flowing and compressing into a solid tablet to maintain tablet dimensions and drug dosage as desired. Upon testing, formulas 1-3 demonstrated significantly higher flow rates compared to other formulas (p<0.001). When observed, the use of HPMC and Carbopol separately (F1 and F2) and their combination in a 1:1 ratio resulted in a better flow rate than their combination with an imbalanced ratio in one of the polymers (see Figure 2). The addition of HPMC to the Carbopol formula decreased the flow rate, although not significantly at the same mixed ratio, but significantly at an imbalanced ratio in one of the polymers. The use of a lubricant in F2 may further improve its flowability.

Regarding compressibility, F2 also exhibits greater compressibility compared to other formulas. It is evident here that the use of HPMC, whether alone or in combination with Carbopol, significantly reduces its compressibility. The compressive strength of granules into tablets has indeed been reported to increase with the use of Carbopol (11). Carbopol itself is commonly employed in direct compression tablets (12).

Figure 2. Flow rate (A) and compressibility (B) of the floating granules. Note: (*, p<0.001) shows a significant difference to group F4, and (#, p<0.001) shows a significant difference to group F5.

Granules Swelling

Capacity

The swelling capacity of the granules was observed to occur rapidly at the 15-minute mark for all formulas except for F5. F1 and F2 continue to exhibit significant expansion at the 30-minute mark and plateau thereafter (see Figure 3). In contrast to other formulas using a combination of HPMC and Carbopol, their granules show expansion until the 15-minute mark but stabilize afterward. Unlike other formulas, F5 itself did not exhibit significant expansion and even reverted to its initial weight after 15 minutes in the medium (see Figure 3). This may be attributed to the interaction between the C=O groups of Carbopol and the hydroxyl groups of HPMC (13). This interaction may inhibit the swelling capacity of each other.

Figure 3. Swelling capacity of formulated granules.

Metabolites Content After Formulation

Based on the characterization conducted on the five formulas, F2 exhibits the most favorable characteristics. Therefore, the assessment of metabolite levels in clove leaf extract was performed only on F2 to examine the availability of active metabolites after granulation. If calculated, the total alkaloid, flavonoid, saponin, and tannin in 100 mg of granules are 9.2 mg, 14.5 mg, 4.8 mg, and 0.3 mg, respectively (see Table 2). If tablets weighing 500 mg are produced, each tablet will contain 72.5 mg of flavonoids equivalent to quercetin. Quercetin has been widely used in some countries in products with doses ranging from 10-125 mg/administration and 200-1200 mg/day. The amount of quercetin in F2 is still relatively high for use as a health supplement. From this, it can be observed that the wet granulation process for clove leaf effectively preserves the desired metabolite levels.

Table 2. Determination of secondary metabolite content in Formula 2.

|

No. |

Test parameter |

Result (%) |

Linear regression |

|

1. |

Total alkaloid equivalent to quinine |

0.0920% |

y=0.0369x + 0.0171 |

|

2. |

Total flavonoid equivalent to quercetin |

0.1449% |

y=0.0003x + 0.0132 |

|

3. |

Total saponin equivalent to sapogenin |

0.048% |

y=0.0087x + 0.1236 |

|

4. |

Total tannin equivalent to tannic acid |

0.0037% |

y=0.0203x + 0.1762 |

Conclusion

Based on the obtained results, the swelling granules from clove extract exhibited favorable properties, with the optimal composition being 210 mg of Carbopol, 36 mg of PVP, and 404 mg of Avicel pH 101. These granules demonstrated uniform particle size distribution, with 90.1% falling below 149 µm (passing through mesh number 100), and 9.9% distributed across mesh numbers 100, 80, and 40. The flow rate, compressibility, and swelling capacity of the formula with Carbopol polymer were also superior to other formulations. The interaction between the C=O groups of Carbopol and the hydroxyl groups of HPMC showed a significant influence on the tested parameters, particularly on the swelling capacity. Therefore, when combining polymers, consideration should be given to potential chemical or physical reactions. The wet granulation process employed also effectively maintained the levels of secondary metabolites from clove leaf. Moving forward, activity tests should be conducted to assess the effectiveness of granulation as a delivery system for clove leaf extract.

Declarations

Ethics Statement

Not applicable.

Data Availability

The unpublished data is available upon request to the corresponding author.

Funding Information

The authors thank to the Pelita Mas Palu Foundation for funding this research with grant number 004/STIFA-PL/Lemlit/XII/2022.

Conflict of Interest

The authors declare no conflicting interest.

References

- Abdul Aziz AH, Rizkiyah DN, Qomariyah L, Irianto I, Che Yunus MA, Putra NR. Unlocking the Full Potential of Clove (Syzygium aromaticum) Spice: An Overview of Extraction Techniques, Bioactivity, and Future Opportunities in the Food and Beverage Industry. Processes. 2023 Aug 15;11(8):2453.

- El-Saber Batiha G, Alkazmi LM, Wasef LG, Beshbishy AM, Nadwa EH, Rashwan EK. Syzygium aromaticum L. (Myrtaceae): Traditional Uses, Bioactive Chemical Constituents, Pharmacological and Toxicological Activities. Biomolecules. 2020 Jan 30;10(2):202.

- Issac A, Gopakumar G, Kuttan R, Maliakel B, Krishnakumar IM. Safety and anti-ulcerogenic activity of a novel polyphenol-rich extract of clove buds (Syzygium aromaticum L). Food Funct. 2015;6(3):842–52.

- Zhang W, Lian Y, Li Q, Sun L, Chen R, Lai X, et al. Preventative and Therapeutic Potential of Flavonoids in Peptic Ulcers. Molecules. 2020 Oct 11;25(20):4626.

- Pinheiro de Souza F, Sonego Zimmermann E, Tafet Carminato Silva R, Novaes Borges L, Villa Nova M, Miriam de Souza Lima M, et al. Model-Informed drug development of gastroretentive release systems for sildenafil citrate. Eur J Pharm Biopharm. 2023 Jan;182:81–91.

- Vinchurkar K, Sainy J, Khan MA, Mane S, Mishra DK, Dixit P. Features and Facts of a Gastroretentive Drug Delivery System-A Review. Turkish J Pharm Sci. 2022 Aug 31;19(4):476–87.

- Satishbabu B, Ravi R, Sandeep V, Shrutinag R. Formulation and evaluation of floating drug delivery system of famotidine. Indian J Pharm Sci. 2010;72(6):738.

- Brady J, Dürig T, Lee PI, Li JX. Polymer Properties and Characterization. In: Developing Solid Oral Dosage Forms. Elsevier; 2017. p. 181–223.

- Suhail M, Wu PC, Minhas MU. Using Carbomer-Based Hydrogels for Control the Release Rate of Diclofenac Sodium: Preparation and In Vitro Evaluation. Pharmaceuticals. 2020 Nov 17;13(11):399.

- Hadinugroho W, Martodihardjo S, Fudholi A, Riyanto S, Prasetyo J. Hydroxypropyl Methylcellulose as Hydrogel Matrix and Citric Acid-Locust Bean Gum as Negative Matrix for Controlled Release Tablet. ACS Omega. 2023 Feb 28;8(8):7767–78.

- Aguilar-López YA, Villafuerte-Robles L. Functional Performance of Chitosan/Carbopol 974P NF Matrices in Captopril Tablets. J Pharm. 2016 Oct 25;2016:1–9.

- Khan GM, Jiabi Z. Formulation and in vitro evaluation of ibuprofen-carbopol® 974P-NF controlled release matrix tablets III: influence of co-excipients on release rate of the drug. J Control Release. 1998 Jul;54(2):185–90.

- Fayed MH, Mahrous GM, Ibrahim MA, Sakr A. Influence of Carbopol 71G-NF on the release of dextromethorphan hydrobromide from extended-release matrix tablets. Pharm Dev Technol. 2013 Oct 3;18(5):971–81.

ETFLIN

Notification

ETFLIN

Notification