Optimization of Cream Formulation with Borneo Tallow Nut, Almond Oil, and Olive Oil Using the Simplex Lattice Design Method

by Maria Elvina Tresia Butar-Butar ★ , Muh Taufiqurrahman, Adhe Septa Ryant Agus, Dwi Retno Sari, Selvina Selvina, Santa Eufrasia Carolin Tokan

Academic editor: Garnadi Jafar

Sciences of Pharmacy 3(4): 212-219 (2024); https://doi.org/10.58920/sciphar0304260

This article is licensed under the Creative Commons Attribution (CC BY) 4.0 International License.

30 Jun 2024

13 Nov 2024

16 Dec 2024

17 Dec 2024

Abstract: Dry skin, a common dermatological issue affecting individuals across all age groups, often disrupts the skin's protective barrier, leading to discomfort and increased sensitivity. Addressing this condition involves the use of moisturizers, which play a vital role in restoring skin hydration. In this study, a cream preparation was successfully developed using vegetable oils, including Borneo Tallow Nut, Almond Oil, and Olive Oil. The cream formula was optimized using the Design-Expert software with the Simplex Lattice Design (SLD) method to evaluate the impact of different concentrations of these oils on the cream's pH, viscosity, spreadability, and adhesion. The results demonstrated that the cream exhibited excellent thermo-physical stability, with optimum values of Borneo Tallow Nut at 1.349% w/w, Almond Oil at 3.598% w/w, and Olive Oil at 4.051% w/w. The cream achieved a pH value of 5.702, viscosity of 16.851 Cp, spreadability of 8.147 cm, and adhesion of 63.682 s, with a desirability score of 0.718. This research confirms that Borneo Tallow Nut, Olive Oil, and Almond Oil have significant potential as excipients in cream formulations.

Keywords: Vegetable oilsCream spreadabilityDry skin creamCream excipients

Introduction

Skin is a multifunctional organ responsible for thermoregulation, protection against pathogens, and maintaining hydration through its barrier function. A healthy skin barrier requires the stratum corneum to maintain a moisture content of over 10% (1). However, environmental factors such as low humidity, UV radiation, and chemical exposure can disrupt this balance, leading to conditions like dry skin or xerosis cutis, characterized by roughness, scaling, and reduced elasticity (2, 3). Repeated exogenous exposure can disrupt the skin barrier in maintaining water content and lipid disruption in the stratum corneum, thus triggering Transepidermal Waterloss (TEWL) (4). The prevalence of dry skin in Indonesia reaches 50-80% (5). This highlights the critical need for effective strategies and formulations to restore and maintain the skin's barrier function, ensuring proper hydration and overall skin health.

Natural Moisturising Factor (NMF) compounds, produced by the skin, help maintain hydration by attracting water to the stratum corneum. However, NMF levels can become insufficient under certain conditions, necessitating the use of moisturizers (6). These products reduce transepidermal water loss (TEWL), repair the skin barrier, and restore softness (7). Modern moisturizers often combine occlusive, humectant, and emollient agents to provide effective hydration while avoiding greasiness, a common drawback of overly occlusive formulations (8). Using overly occlusive ingredients produces a greasy effect that may affect acceptability. Therefore, it is necessary to add emollient ingredients to provide a gentle effect on the skin (9).

Recent trends in skincare research have shifted towards natural ingredients, including vegetable oils, for their multifunctional benefits. Borneo Tallow Nut, Almond Oil, and Olive Oil are rich in fatty acids like oleic acid and linoleic acid, as well as bioactive compounds such as beta-sitosterol and squalene, which offer skin-softening, anti-inflammatory, and antioxidant properties. These oils have shown the potential to restore the skin barrier, reduce TEWL, and reduce irritation (10-12). Oleic acid softens the skin, regenerates skin cells, moisturizes the skin, and is a natural anti-inflammatory. Linolear acid helps restore skin barrier function and reduces TEWL. Beta-sitosterol works to reduce itching and redness and soothe irritated skin. Squalene regenerates cells and acts as an antioxidant by protecting the skin from UV-induced lipid peroxidation (13, 14).

Based on the potential of vegetable oils, in this research, we developed moisturizing products in cream preparations with varying concentrations of Borneo Tallow Nut, Almond Oil, and Olive Oil, which were designed using Design-Expert Version 11 to determine the effect of different concentrations of vegetable oils on the physical characteristics of the cream, including organoleptic, homogeneity, pH, viscosity, spreadability, adhesion, and stability.

Methodology or Experimental Section

Materials

The main ingredients are Borneo tallow nut (Shorea mecistopteryx) (sample given from Balai Besar Penelitian dan Pengembangan Ekosistem Hutan Dipterokarpa, Indonesia), olive oil (Olea europaea) (NG Agro Farm Ltd., Indonesia), almond oil (Oleum amygdalae) (NG Agro Farm Ltd., Indonesia), lipomulse luxe (Vantage Specialty Chemicals, Inc., USA), triethanolamine (Reagent Grade, T58300, Sigma Aldrich, USA), edetate disodium (USP Reference Standard, 1233009, Sigma Aldrich, USA), isopropyl myristate (USP Reference Standard, 1350400, Sigma Aldrich, USA), propylene glycol (USP Grade, PHR1051, Supelco®, Merck KGaA, Germany), dimethylol-5-5-dimethylhydantoin (USP Grade, PHR1358, Supelco®, Merck KGaA, Germany), water.

Tools

The tools used in this study were analytical balance (FS-AR210INT-CAL, Fujitsu Ltd., Japan), hot plate (HP380-Pro LCD Digital Hotplate, Scilogex LLC., USA), pH meter (AZ® 86555, AZ Instrument Corp., Taiwan), brookfield viscometer (DVNext Rheometer, AMETEK Inc., USA), stopwatch, and laboratory glassware.

Preparation of Cream

A Simplex Lattice Design (SLD) was adopted to optimize the formulation variables. The design formula for cream preparation can be seen in Table 1. The Borneo tallow nut, almond oil, olive oil, lipomulse luxe, and isopropyl myristate were melted in a hot plate at 70-80 °C (Mixture #1). Edetate disodium, propylene glycol, TEA, and DMDM hydantoin were dissolved in a hot plate at 70-80°C (Mixture #2). Mixture #2 was put into a hot mortar, and Mixture #1 was added. Both phases were mixed slowly with continuous stirring to form a homogeneous dispersion while maintaining the temperature at 35-40°C, resulting in a creamy mass.

Evaluation of Cream

Organoleptic Test

The organoleptic test is intended to see the physical appearance of the cream, including its shape, color, and smell. The test specifications can be seen in Table 2.

pH Measurement

The pH of the 10% w/v cream suspension was measured at 25°C using a calibrated pH meter. It is essential for moisturizers to have a pH that closely aligns with the skin's natural pH, typically between 4.5 and 6.5, to avoid adverse effects. A too acidic pH may irritate, while an excessive pH of alkaline can lead to dryness. Before measurement, the pH meter was calibrated using standard buffer solutions with pH values of 4.0 and 7.0 to ensure accuracy (15).

Table 1. Composition of all formulations of cream.

|

Ingredients |

Formulation codes (% w/w) |

|||||||||||

|

F1 |

F2 |

F3 |

F4 |

F5 |

F6 |

F7 |

F8 |

F9 |

F10 |

F11 |

F12 |

|

|

Borneo tallow nut |

1 |

2 |

2 |

1.54 |

1 |

1.15 |

1.18 |

2 |

1.36 |

2 |

1.18 |

1.20 |

|

Almond oil |

4.38 |

2 |

3.41 |

3.20 |

3.55 |

2.75 |

2 |

4 |

3.79 |

2.55 |

2 |

4.79 |

|

Olive oil |

3.61 |

5 |

3.58 |

4.24 |

4.44 |

5.09 |

5.82 |

3 |

3.83 |

4.44 |

5.82 |

3 |

|

Lipomulse luxe |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

Isopropyl myristate |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

TEA |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

|

Edetate disodium |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

|

Propylene glycol |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

|

DMDM hydantoin |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

0.074 |

|

Water ad libitum |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

Table 2. Assessment criteria for homogeneity examination of cream.

|

Criteria |

Description |

|

Not homogeneous |

The preparation separates, and there are coarse grains or fulfills one of the criteria (separate only or there are only coarse grains)

|

|

Homogeneous |

The preparation does not separate, and there are no coarse grains

|

Table 3. Results of vegetable oils cream organoleptic observation.

|

Formulation |

Color |

Smell |

Shape |

|

F1 |

White |

Odorless |

Semi solid |

|

F2 |

Yellowish white |

Odorless |

Semi solid |

|

F3 |

Yellowish white |

Odorless |

Semi solid |

|

F4 |

White |

Odorless |

Semi solid |

|

F5 |

White |

Odorless |

Semi solid |

|

F6 |

White |

Odorless |

Semi solid |

|

F7 |

White |

Odorless |

Semi solid |

|

F8 |

Yellowish white |

Odorless |

Semi solid |

|

F9 |

White |

Odorless |

Semi solid |

|

F10 |

Yellowish white |

Odorless |

Semi solid |

|

F11 |

White |

Odorless |

Semi solid |

|

F12 |

White |

Odorless |

Semi solid |

Homogeneity

The homogeneity test method was conducted with modifications. Approximately 0.5 g of the cream was applied to a glass slide or another suitable transparent material. The formulation was assessed for a uniform appearance, ensuring no visible coarse particles were present. The criteria for evaluating homogeneity are detailed in Table 3.

Viscosity

Spreadability

The spreadability test was conducted to evaluate the formulation's ability to spread effectively when applied to the skin. An ideal moisturizer was expected to spread easily, ensuring optimal coverage and efficacy, with a target spreadability diameter of 5–7 cm. For the test, 0.5 g of the cream was placed on a transparent glass sheet positioned over graph paper. The formulation was allowed to spread naturally, after which it was covered with another transparent glass sheet. A 50 g weight was applied for 1 min, and the resulting spread diameter was measured (16).

Adhesion

A total of 0.5 g of preparation were spread on the disc glass, and on top of it, another glass was placed and pinned under a load of 250 g for 1 min. Then, the disc glass was mounted on the test equipment and weighed 250 g. The load was released, and the time was recorded up to the second object of the glasses falling off.

Stability

The cycling test was conducted over six cycles. The cream formulations were stored at a cold temperature (approximately 4°C) for 24 h, then transferred to a warm environment at approximately 40°C. This sequence constituted one complete cycle.

Result and Discussion

Evaluation of Cream

The development of topical products currently leads to the back-to-nature trend because they are considered relatively safer. This phenomenon provides an opportunity to explore the potential of vegetable oils as topical products that function as moisturizers.

Organoleptic Test

Organoleptic observations of the cream included an assessment of its odor, color, and texture. These observations were conducted to monitor the physical characteristics of each formulation during storage at room temperature (20–25°C) over 28 days. The results of the organoleptic evaluation are presented in Table 3.

Organoleptic observations revealed noticeable differences in color, with higher concentrations of Borneo tallow nut resulting in a yellowish-white hue in the cream formulations (F2, F3, F8, F10). This color change is likely due to the natural pigments present in Borneo tallow nuts, which can impart a yellowish tint when used in higher concentrations. Similar findings have been reported in previous studies, where the inclusion of certain plant oils or extracts led to color variations in cream formulations, reflecting the presence of natural compounds such as carotenoids or other phytochemicals (17). The color variation could also influence consumer perception, as natural colorants are often associated with the product's authenticity and quality. However, the color change did not significantly affect the other physical characteristics or the overall acceptability of the cream, indicating that it remained a stable and effective formulation despite the visual difference.

Homogeneity

Test

The homogeneity test was conducted to assess the presence or absence of coarse particles in the cream formulations. The results indicated that all formulas were homogeneous, with no visible coarse grains detected. This suggests that the ingredients in the formulations were well-mixed and uniformly distributed. The absence of coarse grains is a positive indicator of the cream's quality, as it suggests that the emulsification process was successful, ensuring a smooth and consistent texture.

Stability

During storage, thermal stability, viscosity, and spreadability are critical parameters that influence the acceptability of topical product formulations. This study showed that all formulations exhibited good stability when stored at 4°C and 40°C. None of the formulations experienced phase separation, and there were no noticeable color, odor, or texture changes. This suggests that the cream formulations maintained their structural integrity and overall appearance under cold and warm storage conditions, indicating robust thermal stability.

These findings are consistent with previous studies on cream formulations that employed natural oils and emulsifiers, where good thermal stability was observed, often attributed to the balanced composition of the formulation and the proper selection of stabilizers (18). Phase separation is a common issue in emulsions, especially under extreme temperature conditions; however, the formulations in this study were well-protected against such instability. This stability is essential for ensuring the shelf-life and consumer acceptability of the product. The absence of significant changes in physical properties further supports the potential for these formulations to be used effectively as topical moisturizers, offering consistent performance over time.

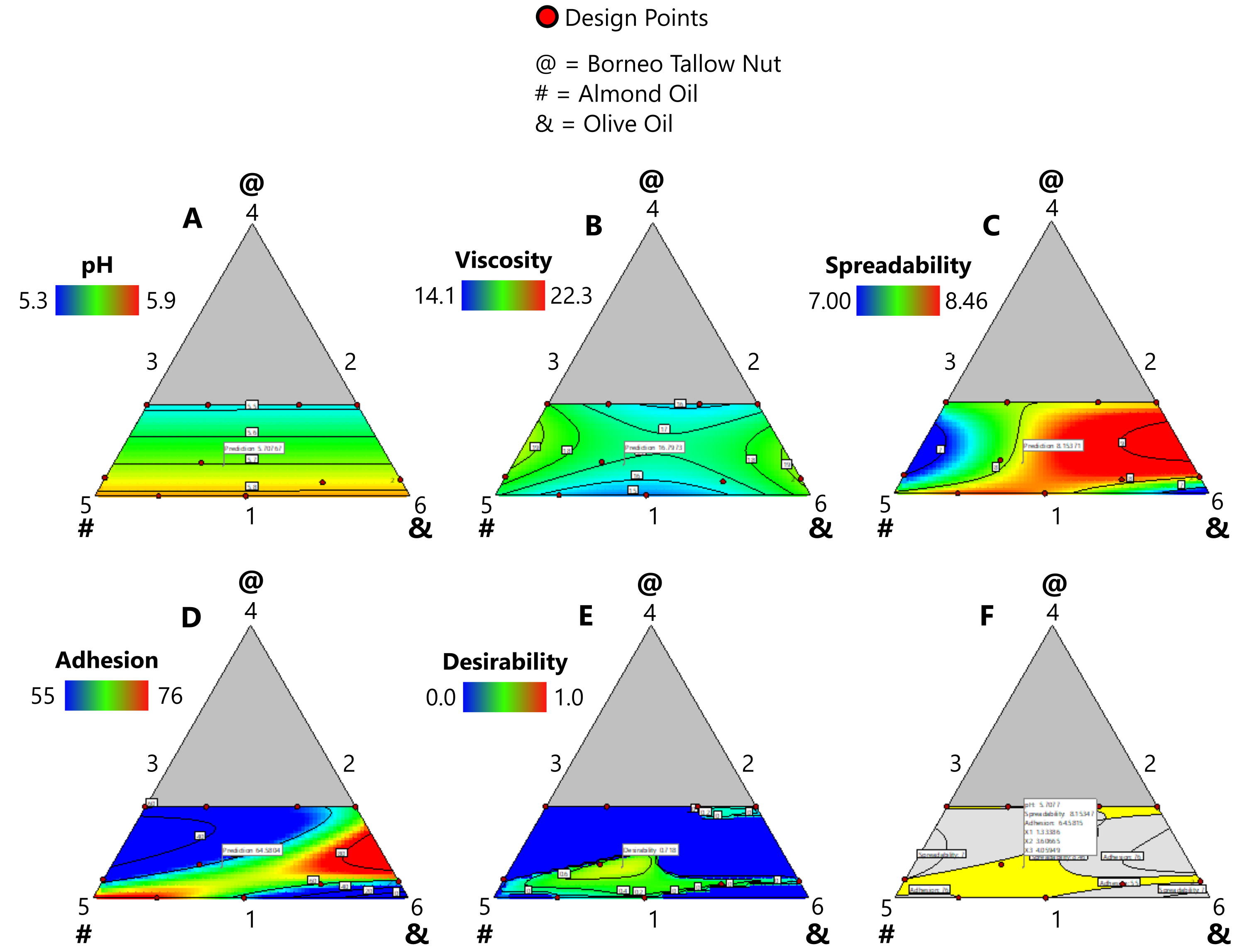

Response Surface Methodology

The influence of the main effects on the response was further examined using response surface methodology (RSM), a widely employed technique in developing and optimizing dosage formulations. The corresponding two-dimensional contour response surface plots were generated using the Design of Experiments (DoE) software. These plots are valuable for visualizing independent variables' main effects and interactions, clearly representing how the formulation components influence the response variables (see Figure 1).

Figure 1. Surface response plot showing the effect of Borneo tallow nut (@), almond oil (#), and olive oil (&) on cream’s pH (A), viscosity (B), spreadability (C), adhesion (D), and desirability (E), and their combination effect (F).

Impact on pH

The pH response was described by the equation Y = 4.80902 (Borneo Tallow Nut) + 5.81892 (Almond Oil) + 5.82216 (Olive Oil). This equation suggests that all three ingredients (Borneo Tallow Nut, Almond Oil, and Olive Oil) showed a positive interaction, indicating that the combined concentrations of these oils did not significantly alter the pH of the cream formulation.

The lack of significant change in pH observed here is consistent with findings from previous studies, where formulations containing vegetable oils or natural ingredients showed relatively stable pH values, as these ingredients are often close to the skin's natural pH (19). The minimal impact on pH could be attributed to the buffering capacity of the oils, which may help maintain the cream's acidity within the optimal range for skin applications, typically between 4.5 and 6.5. This stability in pH is important for ensuring the product's compatibility with the skin and preventing potential irritation.

Impact on Viscosity

The effect on viscosity was described by the equation Y = -22.6556 (A) (Borneo Tallow Nut) + 17.063 (B) (Almond Oil) + 18.9514 (C) (Olive Oil) + 63.5282 (AB) (Borneo Tallow Nut and Almond Oil) + 50.6194 (AC) (Borneo Tallow Nut and Olive Oil) - 12.3465 (BC) (Almond Oil and Olive Oil). According to this equation, there was a negative interaction between Borneo Tallow Nut and the combination of Almond Oil and Olive Oil, with values of -22.6556 and -12.3465, respectively. This suggests that as the concentrations of Borneo Tallow Nut, Almond Oil, and Olive Oil decreased, the viscosity of the cream also decreased.

The observed negative interaction for Borneo Tallow Nut implies that its presence in higher concentrations could increase the viscosity while reducing its concentration could decrease the overall viscosity of the formulation. Similarly, the combination of Almond Oil and Olive Oil had a negative interaction, further supporting that lower concentrations of these ingredients would reduce the cream's viscosity.

This finding aligns with previous studies, which reported that oils with higher viscosity, such as olive oil, generally increase the overall viscosity of topical formulations (20). However, when combined with other oils, the viscosity may decrease depending on the interactions between the oils' components. For instance, the viscosity-lowering effect observed when reducing Almond Oil and Olive Oil concentrations may be related to their fluidizing properties, which reduce the overall viscosity when combined in certain ratios (21). Thus, the formulation's viscosity can be controlled by adjusting the concentrations of the individual oils to achieve the desired texture and spreadability for optimal skin application.

Impact on Spreadability

The effect on spreadability was described by the equation Y = -2.79063 (A) (Borneo Tallow Nut) + 8.14071 (B) (Almond Oil) + 6.14681 (C) (Olive Oil) + 27.6676 (AB) (Borneo Tallow Nut and Almond Oil) + 9.77358 (AC) (Borneo Tallow Nut and Olive Oil) + 4.03451 (BC) (Almond Oil and Olive Oil) - 11.511 (ABC) (Borneo Tallow Nut, Almond Oil, and Olive Oil). The equation revealed a negative interaction between Borneo Tallow Nut and the combined oils (with a value of -11.511), indicating that as the concentration of Borneo Tallow Nut decreased, the spreadability of the cream was negatively affected, leading to reduced spreadability. Furthermore, adding the three oils in smaller concentrations had a similar impact, decreasing the cream's spreadability.

This observation can be explained by the unique properties of Borneo Tallow Nut, which likely has a higher viscosity than Almond Oil and Olive Oil. Borneo Tallow Nut may increase the cream's overall consistency when included in larger concentrations, making it less spreadable. On the other hand, combining all three oils in smaller amounts seems to interact synergistically, with a slight reduction in spreadability. This suggests that lower concentrations of the oils result in a formulation with less fluidity and easier spreadability.

These findings are consistent with previous studies, showing that oils with higher viscosities or thicker textures reduce spreadability (22). Conversely, lighter oils often improve spreadability due to their fluid nature. For example, Almond Oil and Olive Oil are generally considered emollients that enhance skin smoothness and facilitate the easy spreading of formulations (9, 23). However, as seen in this study, the interaction between oils can lead to a complex balance, where the combined presence of multiple oils in small amounts can reduce the spreadability compared to individual oils used in higher concentrations. Therefore, the formulation's spreadability can be optimized by adjusting the oil concentrations to balance fluidity and consistency.

Impact on Adhesion

The effect on adhesion was described by the equation Y = 383.5 (A) (Borneo Tallow Nut) + 78.8566 (B) (Almond Oil) -10.4264 (C) (Olive Oil) -6552.05 (AB) (Borneo Tallow Nut and Almond Oil) -6970.06 (AC) (Borneo Tallow Nut and Olive Oil) + 74.8266 (BC) (Almond Oil and Olive Oil) + 6710.19 (ABC) (Borneo Tallow Nut, Almond Oil, and Olive Oil). This equation revealed a negative interaction between Olive Oil and the combinations of Borneo Tallow Nut with Almond Oil (with a value of -6552.05) and Borneo Tallow Nut with Olive Oil (with a value of -6970.06), suggesting that these combinations led to a decrease in the adhesion properties of the cream. However, Almond Oil and Olive Oil showed a positive interaction (74.8266), indicating that their combination enhanced adhesion. The specific characteristics of the oils involved can explain the negative interactions observed. Borneo Tallow Nut, which has a higher molecular weight and a thicker consistency compared to Almond Oil and Olive Oil, may reduce the adhesion of the formulation when combined with these oils. The higher viscosity of Borneo Tallow Nut could create a denser formulation, limiting its ability to adhere effectively to the skin. Additionally, when Borneo Tallow Nut is combined with either Almond Oil or Olive Oil, the overall texture may become too greasy or oily, hindering adhesion. In contrast, the combination of Almond Oil and Olive Oil improved adhesion, likely due to their synergistic effects. Both oils are known for their emollient properties, which may enhance the cream's ability to spread and adhere to the skin. Previous studies have demonstrated that oils with lower viscosities and better skin penetration properties can improve the adhesion of topical formulations (24). Balancing the oils and their respective concentrations may optimize the cream's adhesion by providing a smoother, more flexible texture.

Desirability

After deriving the model equation that links the main effects and responses of various cream formulations containing Borneo Tallow Nut, Almond Oil, and Olive Oil, the optimal values for the response variables were determined to be 1.349 for Borneo Tallow Nut, 3.598 for Almond Oil, and 4.051 for Olive Oil. Based on these values, the optimal formulation achieved a desirability score of 0.718.

This optimal formulation suggests a balanced combination of the three ingredients to achieve the best overall performance, considering factors such as pH, viscosity, spreadability, and adhesion. The desirability value of 0.718 indicates that the formulation closely approached the ideal conditions for these properties, which are crucial for the product's effectiveness and consumer acceptability.

The values for the individual oils reflect their respective contributions to the cream's formulation. Borneo Tallow Nut, being a higher-viscosity component, likely contributes to the formulation's stability and texture, while Almond Oil and Olive Oil, known for their emollient and moisturizing properties, enhance the spreadability and skin feel of the cream. The interaction between these oils creates a formulation that balances thickness and spreadability, essential for a topical cream that provides both effective coverage and ease of application. These findings are consistent with previous studies that have used optimization techniques, such as response surface methodology, to design topical formulations. For example, a study by Trindade G. et al. (2024) used similar approaches to optimize the composition of natural oil-based creams, finding that a balanced combination of oils led to improved physical properties, including better spreadability and adhesion (25).

Conclusion

The present study demonstrated that a cream formulation containing Borneo Tallow Nut, Almond Oil, and Olive Oil exhibited good thermo-physical stability. The optimal formulation was achieved with 1.349% b/b Borneo Tallow Nut, 3.598% b/b Almond Oil, and 4.051% b/b Olive Oil. This formulation showed favorable properties, including a pH of 5.702, viscosity of 16.851 CPs, spreadability of 8.147 cm, and stickiness of 63.682 seconds, with a desirability value of 0.718. These results suggest combining these ingredients can produce a stable and effective cream with desirable physical characteristics for topical use.

Based on the findings, Borneo Tallow Nut, Olive Oil, and Almond Oil are promising excipients for cream formulations, providing a balance of stability, spreadability, and adhesion. These oils, individually and in combination, contribute to the overall performance of the cream, making it suitable for skin care applications. Using response surface methodology, the optimization process successfully identified the optimal concentrations of these oils, underscoring their potential in cosmetic formulations. This study supports the growing interest in natural oils as key components in skin care products, aligning with previous research highlighting the efficacy of such ingredients in enhancing product quality and user satisfaction.

Declarations

Ethics Statement

Not applicable.

Data Availability

The unpublished data is available upon request to the corresponding author.

Funding Information

Not applicable.

Conflict of Interest

The authors declare no conflicting interest.

References

- Bäsler K, Bergmann S, Heisig M, Naegel A, Zorn-Kruppa M, Brandner JM. The role of tight junctions in skin barrier function and dermal absorption. J Control Release. 2016 Nov;242:105–18.

- Wan DC, Wong VW, Longaker MT, Yang GP, Wei FC. Moisturizing different racial skin types. J Clin Aesthet Dermatol. 2014 Jun;7(6):25–32.

- Choi EH. Aging of the skin barrier. Clin Dermatol. 2019 Jul;37(4):336–45.

- Kwan P, Sills GJ, Brodie MJ. Understanding the Role of NMF in Skin Hydration. Pract Dermatology [Internet]. 2012;July(1):21–34. Available from: http://www.ncbi.nlm.nih.gov/pubmed/11448723

- Kursiussamawati FL, Primawati I, Sriwahyuni S. Knowledge Level of Dry Skin Care in The Elderly at The Koto Tangah Regional Health Center. Biomed J Indones. 2024 Mar 1;10(1):1–7.

- Spada F, Barnes TM, Greive KA. Skin hydration is significantly increased by a cream formulated to mimic the skin’s own natural moisturizing systems. Clin Cosmet Investig Dermatol. 2018 Oct;Volume 11:491–7.

- Draelos ZD. The science behind skin care: Moisturizers. J Cosmet Dermatol. 2018 Apr 10;17(2):138–44.

- Nolan K, Marmur E. Moisturizers: Reality and the skin benefits. Dermatol Ther. 2012 May;25(3):229–33.

- Mohiuddin AK. Skin Care Creams: Formulation and Use Related papers. Dermatology Clin Res [Internet]. 2019;5(1):238–27. Available from: www.scitcentral.com

- Fernandes GD, Gómez-Coca RB, Pérez-Camino M del C, Moreda W, Barrera-Arellano D. Chemical Characterization of Major and Minor Compounds of Nut Oils: Almond, Hazelnut, and Pecan Nut. J Chem. 2017;2017:1–11.

- Seçmeler Ö, Galanakis CM. Olive Fruit and Olive Oil. In: Innovations in Traditional Foods. Elsevier; 2019. p. 193–220.

- Jimenez-Lopez C, Carpena M, Lourenço-Lopes C, Gallardo-Gomez M, Lorenzo JM, Barba FJ, et al. Bioactive Compounds and Quality of Extra Virgin Olive Oil. Foods. 2020 Jul 28;9(8):1014.

- Hanum TI, Laila L, Sumaiyah S, Syahrina E. Macadamia Nuts Oil in Nanocream and Conventional Cream as Skin Anti-Aging: A Comparative Study. Open Access Maced J Med Sci. 2019 Nov 14;7(22):3917–20.

- Wall MM. Functional lipid characteristics, oxidative stability, and antioxidant activity of macadamia nut (Macadamia integrifolia) cultivars. Food Chem. 2010 Aug;121(4):1103–8.

- Swastika A, Mufrod, Purwanto. Antioxidant Activity of Cream Dosage Form of Tomato Extract (Solanum lycopersicum L.). Tradit Med J. 2013;18(3):2013.

- Dhyani A, Chander V, Singh N. Formulation and evaluation of multipurpose herbal cream. J Drug Deliv Ther. 2019;9(2):341–3.

- Conboy Stephenson R, Ross RP, Stanton C. Carotenoids in Milk and the Potential for Dairy Based Functional Foods. Foods. 2021 Jun 2;10(6):1263.

- Degner BM, Chung C, Schlegel V, Hutkins R, McClements DJ. Factors Influencing the Freeze‐Thaw Stability of Emulsion‐Based Foods. Compr Rev Food Sci Food Saf. 2014 Mar 21;13(2):98–113.

- Pavlačková J, Kovacsová K, Radiměřský P, Egner P, Sedlaříková J, Mokrejš P. Stability and in vivo efficiency of natural cosmetic emulsion systems with the addition of vegetable oils. Brazilian J Pharm Sci. 2018 Nov 29;54(3).

- Bonnet J, Devesvre L, Artaud J, Moulin P. Dynamic viscosity of olive oil as a function of composition and temperature: A first approach. Eur J Lipid Sci Technol. 2011 Aug 14;113(8):1019–25.

- Kolawole OM, Adesegun AT, Isreal SC, Ayorinde RO, Silva BO. Comparative Evaluation of the Physicochemical, Antimicrobial and Stability profile of Olive oil, Almond oil and Coconut oil-based Emulgels. Trop J Phytochem Pharm Sci. 2024 Jul 3;3(3).

- Mousazadeh M, Mousavi M, Emam-Djomeh Z, Hadinezhad M, Gharibzahedi SMT. Formulation Optimization of Pistachio Oil Spreads by Characterization of the Instrumental Textural Attributes. Int J Food Prop. 2014 Jul 3;17(6):1355–68.

- Franco-Gil ME, Graça A, Martins A, Marto J, Ribeiro HM. Emollients in dermatological creams: Early evaluation for tailoring formulation and therapeutic performance. Int J Pharm. 2024 Mar;653:123825.

- Said dos Santos R, Vecchi CF, Rosseto HC, Bassi da Silva J, Dano MEL, de Castro-Hoshino LV, et al. Emulgels Containing Carbopol 934P and Different Vegetable Oils for Topical Propolis Delivery: Bioadhesion, Drug Release Profile, and Ex Vivo Skin Permeation Studies. AAPS PharmSciTech. 2020 Aug 29;21(6):209.

- Trindade GA de M, Alves LA, Lazo REL, Dallabrida KG, Reolon JB, Bonini JS, et al. Polysaccharide-Stabilized Semisolid Emulsion with Vegetable Oils for Skin Wound Healing: Impact of Composition on Physicochemical and Biological Properties. Pharmaceutics. 2024 Nov 8;16(11):1426.

ETFLIN

Notification

ETFLIN

Notification